Whether it’s for home appliances, healthcare equipment or driving excavators, seal materials and designs must be adapted to highly demanding application microenvironments.

In hellish conditions, where corrosive chemicals jet under high pressure, delicate motors spin at 400,000 rpm and steam hisses through sterilisers at 121°C, our fluid seals remain efficient.

Let's look at sealing performance specifications that seals must reach to be effective under three different industry applications.

1. Appliances

From washing machines to refrigerators, innovation is the lifeblood of home appliance design. Each new model must have better performance, more features and be more sustainable than the previous one.

More features are also added to the traditional purpose. As well as cooking, ovens are now required to have steam and self-cleaning features. Multi-compartment refrigerators and freezers must have internet connectivity and inform you when you’re low on milk.

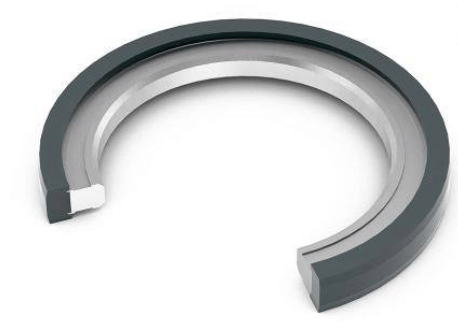

The design of our Simmerring shaft seal delivers reliability and extended operating life to. Simmerring seals are resistant to wear (70 NBR 260866) and harsh chemical environments like detergent and ozone (75 FKM 143898).

2. Healthcare

Our healthcare seals comply with medical approvals/certifications including FDA, USP Class VI and ISO 10993-1, the international standard for evaluating the biocompatibility of medical devices to manage biological risk. They are resistant to very high and low temperatures and are hygienically designed to be free of dead space where bacteria evade cleaning processes.

Hygiene and high temperature stability are key elements in autoclave seal design. Our silicon rubber door seals contain heat stabiliser compounds and are designed to last longer under high pressure steam.

Dental drills contain more than 30 sealing components and protect parts that can move at 300,000-400,000 rpm. We have micro O-ring solutions, micro radial shaft seals, and micro custom moulded parts for the dental profession designed to resist blood, water and other fluids.

3. Fluid handling

Freudenberg has developed seals for the fluid power industry with PTFE and polyurethane compounds. Our innovations have led to the development of accumulators with operating pressure up to 500 bar and radial shaft seals that withstand up to 170 bar (peak).

Materials like our polyurethane AU 30000 allow for operation pressures up to 500 bar, stability in temperatures from –35°C to 120°C and resistance to mineral and biodegradable fluids. We manufacture wipers, rod seals, piston seals and guide rings that keep power hydraulic systems running cleanly and smoothly.

With our comprehensive range of cleverly-designed materials, along with ingenious design, finding the exact seal with the right sealing performance specifications for your needs will never be a problem!