If you’ve seen an excavator or a tilt truck in action, you’ve witnessed the power of hydraulic cylinders and the sealing systems that enable them. Using the pressure of fluid inside a sealed cylinder to drive a piston, no method of linear motion is as strong and efficient.

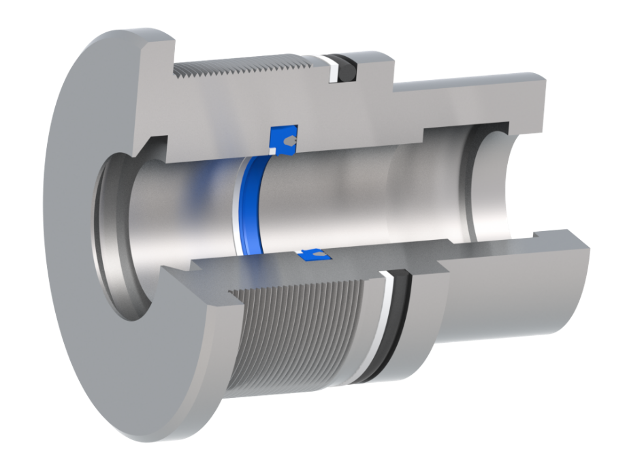

Hydraulics depend on three types of sealing systems to keep out dirt and contain the hydraulic fluid.

1. Piston seals - HDP 330

Inside the cylinder the piston is driven by hydraulic pressure to move the outer rod attached to the load. Piston seals must have extreme extrusion resistance or risk being forced out of the cylinder, breaking the seal and depowering the piston.

Seals must have good sealing function and fluid drift resistance, plus dynamic sealing function similar or better than PTFE (Teflon). Finally the seals must be resistant to high abrasion resistance with a low friction design.

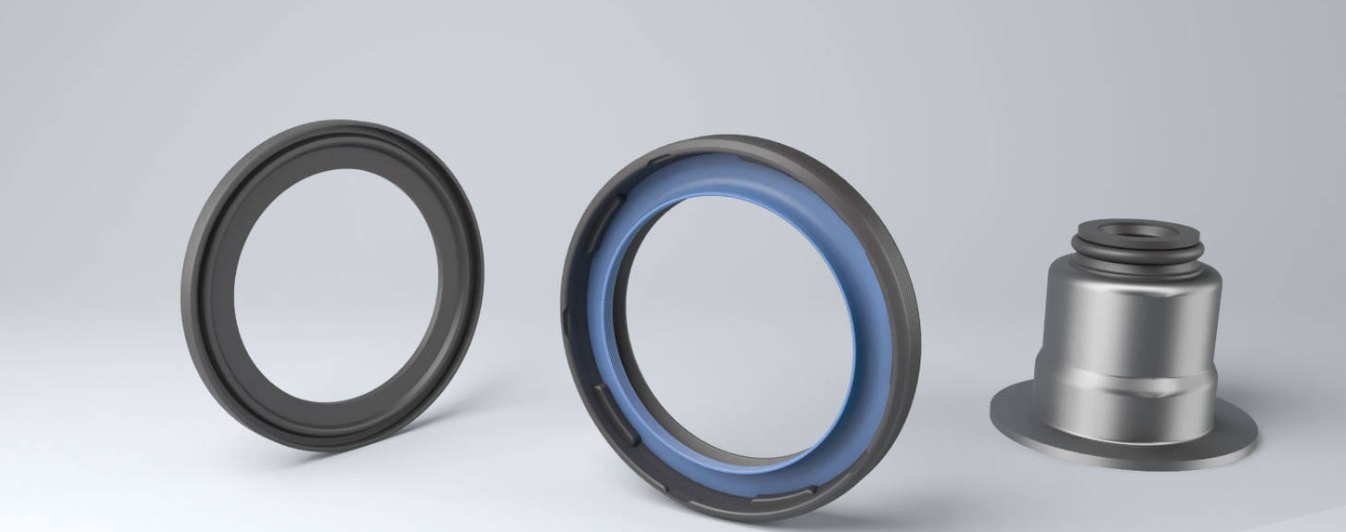

Our HDP 330 design series is a nylon, two-part seal set, consisting of a PA slide ring with a stepped cut and an elastomer energising element for producing pre-load. It has extreme strength against gap extrusion thanks to the PA sliding component, and high abrasion resistance.

The slide ring is made of fibreglass-filled modified polyamide, the contact pressure element of nitrile rubber, giving it a dynamic and static tightness comparable to PTFE piston seals.

2. Rod seals - AU30000

Driven by the piston, the rod extrudes from the cylinder and moves both within the cylinder and in the outside environment. As such, it’s critical that the seal around the rod/cylinder aperture is tight to stop contamination of cylinder fluid and pressure loss.

Any seal in this environment needs high extrusion resistance, broad chemical resistance and resistance to being broken down by exposure to water. It must also tolerate a temperature range from -40°C to 120°C.

The solution is the AU30000, a polyurethane seal that handles larger extrusion gaps or pressure limit increases by 25%. It tolerates a wide range of oils (mineral and synthetic) and additives as well as biodegradable oils for environmentally sensitive contexts.

3. Guide bands - ISG Guivex

A hydraulic guide band (aka wear ring or guide ring) keeps the piston and piston rod on track, absorbing transverse forces that might cause them to move at an angle to the cylinder casing and preventing metal on metal contact.

The imperial-sized ISG Guivex series guide bands are profiled piston and rod guide bands made with a new carbon-fibre filled polyamide material. These bands allow hydraulic cylinder manufacturers to use them in radial load capacities that are 40% higher than standard guide bands.

The innovations in these three FST designs form the basis of a durable, tight, dependable sealing system for any hydraulic cylinder. Contact us or visit our e-Catalogue to see the full range.