Sealing systems ensure the integrity of heavy industrial machinery by isolating it from the outside world. Whether its water, dust, air or oil, sealing systems are the border between external and internal conditions.

Let's look at examples of where customised seals are needed in heavy industry, including industrial presses and mining.

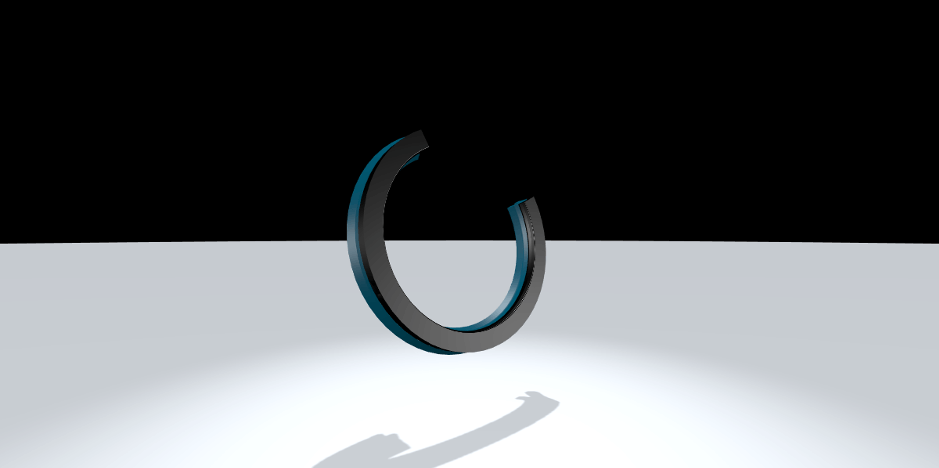

Merkel Omegat sealing system

In industrial presses and forming machines, operating conditions for sealing systems in hydraulic cylinders include high pressure. One solution to withstand the pressure is the Merkel Omegat primary seal, with its customised pressure-relief design.

The cylinder’s changing rate of strokes can lead to extrusion and sealing system failure. But the Merkel Omegat seal has a small borehole in the primary seal allowing return flow of fluid into the working chamber, thereby balancing the pressure.

Mining industry sealing needs

In tunnel boring equipment, there can be peak pressures of up to 250 MPa, which require special sealing designs. Since these can be extremely specific to location, type of operation and size of the machinery, customised sealing must be developed.

At Freudenberg, we collaborate with clients on sealing system installation proposals. These include all the components of the seal system including dimensions and tolerances, the maximum guide stresses and the resulting individual clearances. These proposals mean the client receives the specific sealing system they need for the job.

Maintenance key to asset lifespan

Given the stresses and safety regulations that inform their design, heavy industrial sealing solutions are key to maintenance. For example, it’s estimated that a mine could spend 35% to 50% of its operating budget on equipment maintenance and repair.

Non-working equipment due to a failed seal means the company suffers downtime and financial loss. To combat this, sensors can be embedded into physical assets to monitor wear and tear, and perform maintenance before a fault develops further.

Improper maintenance and incorrect seals will shorten the lifespan of equipment and contribute to down time. With customised sealing systems, maintenance and a meticulous logbook, heavy industrial machinery will have a long and productive asset lifecycle.